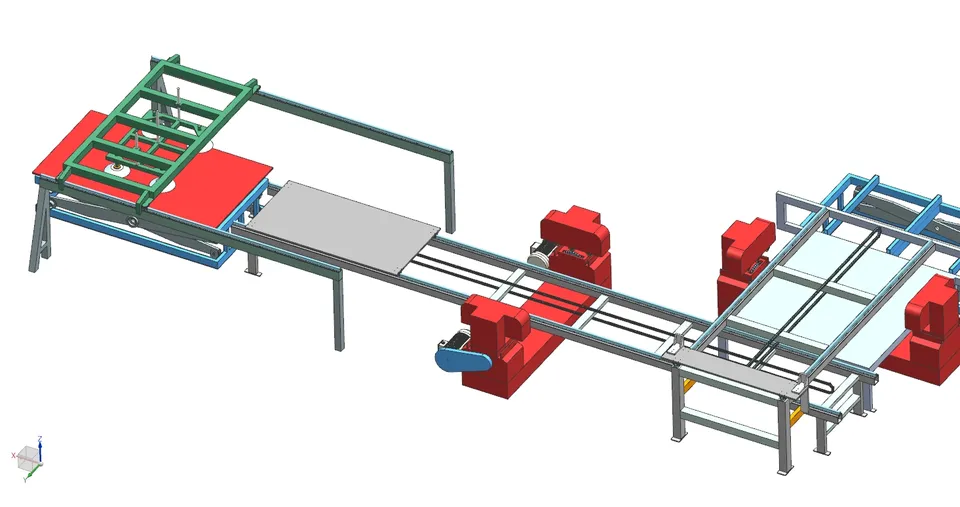

Plywood Cutting Saw machine is a mechanical equipment often used in plywood processing, which is generally used for trimming or fixed-length plywood processing.

Plywood cutting saws can be widely used for high-precision blanking in furniture factories, packaging factories, wooden door factories, electrical appliances factories (lighting), etc. It can be used for precision cutting of particleboard, density board, MDF, multilayer board, plywood, plastic board, acrylic board, PS board, gypsum board, circuit board, solid wood board, etc.

| Cutting size | 3*6ft-4*8ft(adjustable) |

| Motor power | 7.5kw*4pcs |

| Max.thickness of cutting | 60mm |

| loading speed | 40-70m/min |

| Blade line speed | 90- 120m/S |

| Diameter of blade | 305mm |

| Additional parts | Lift table(1 PC);Dust-remover(1 PC) |

| Working style | Red ray guidance |

1. The machine adopts automatic positioning and automatic feeding mode for cutting. After inputting the required target plate size and quantity to the touch screen of the machine, start the machine, and the machine will automatically grab the plate and fix the size for horizontal and vertical cutting;

2. During the cutting process, the automatic lifting and pressing beam is equipped to press the plate tightly. The motor drives the saw car to drive forward, and the saw car automatically moves forward and backward on the linear precision guide rail for cutting;

3. After cutting the last plate, the plate will be automatically pushed out and the size of the next plate to be cut will be positioned. The grinding level gear rack drive can ensure that the sawing error is as low as ± 0.1mm without using an electronic ruler and directly through mechanical hardware;

4. After dynamic balance treatment and rotation test, the saw base is of forward and reverse sawing structure, with excellent straightness of guide rail, forward and reverse sawing of large and small saw blades, without edge chipping, burning and burring, excellent straightness, and diagonal deviation as low as ± 0.2mm;

5. The machine structure is reasonable, stable and solid. The table top is made of 25mm thick high-quality steel and processed by large precision equipment. It is compressive and durable. It can be laminated and cut 100mm thick. It can withstand heavy pressure for a long time without deformation, solid and durable;

6. The feed inlet is equipped with a manual pull emergency stop device, and the discharge outlet is equipped with a photoelectric sensing device to ensure the safety of personnel. Infrared scanning shows that the saw blade automatically sinks when there is foreign matter within 10cm from the saw blade and prevents accidents;

7. Parameterized input of the cutting size. Input the target size to the touch screen. After the horizontal sawing is completed, the vertical sawing can be performed directly. It can be operated manually without repeated input. The efficiency is several times that of the sliding table saw.

In the business phone input box,Please enter National telecommunication code and phone number,format like this +86 13385391681

*Content