The mixed sealant applicator (also known as "three in one") is a model that has developed rapidly in recent years. It combines the structural characteristics of single-screw extruder with the advantages of twin-screw extruder, and has the characteristics of high efficiency, energy saving, low noise, etc.

Working principle The twin-screw extrusion system is composed of a pair of parallel meshing helical bodies, one of which is the drive thread and the other is the feed thread; The material moves forward along the axial direction under the push of two helices and is plasticized by the extrusion of a pair of mutually meshing diagonal rack; When two pairs of gears mesh, the shear force causes the material to be extruded from the mold cavity to the working area, and then the product is formed after cooling and shaping.

| 功率Power | llkw> I5kw |

| 速度模式Speed control | 变频调速 frequency Speed regulation |

| 升降模式LiR mode | 液压升降 hydraulic lift |

| 胶桶数量 Glue barrel number | 2pcs |

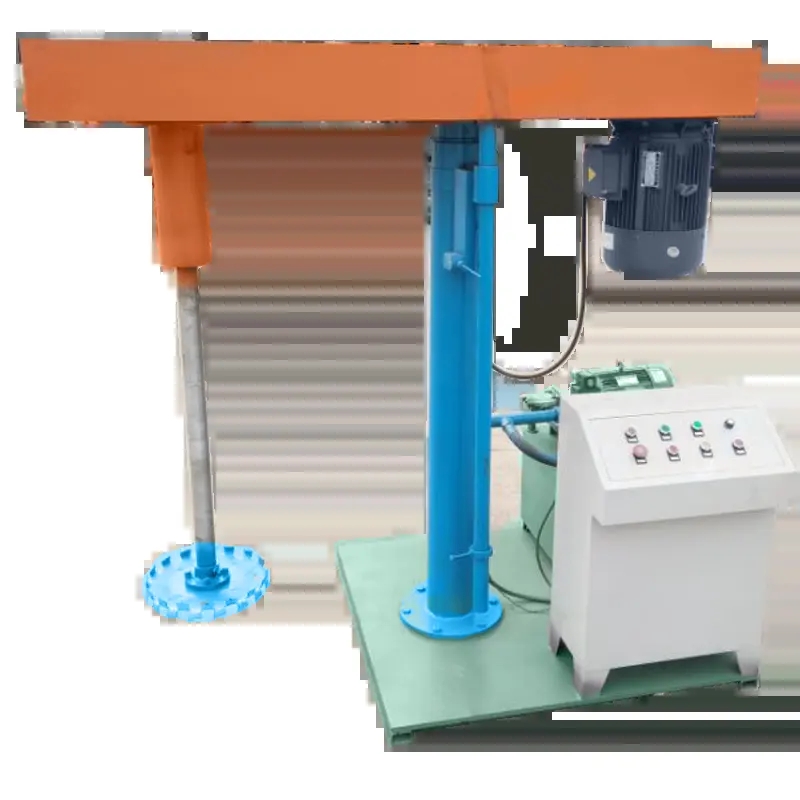

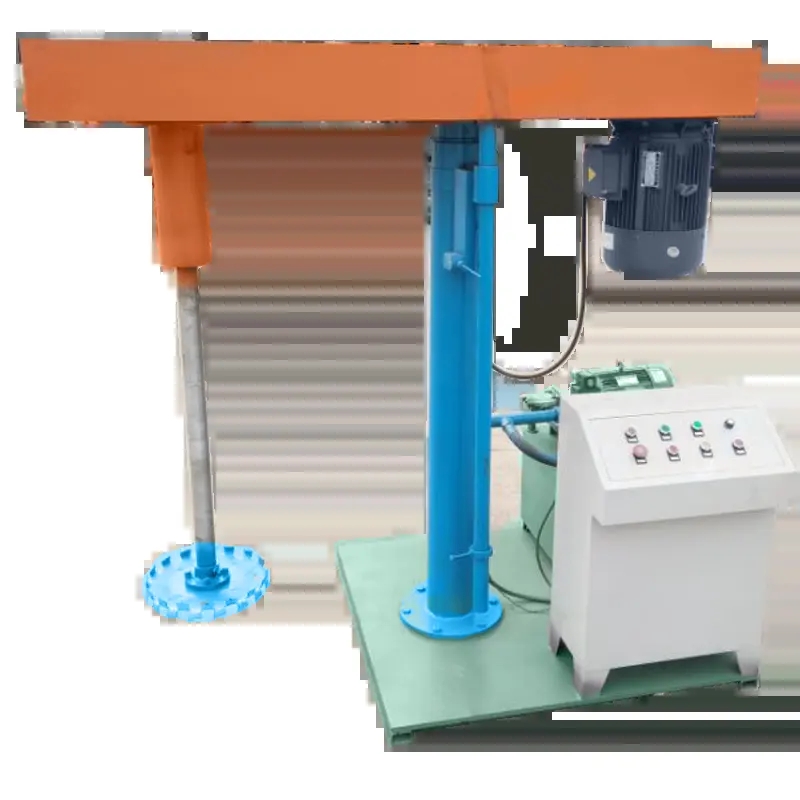

| 立式拌胶机参数 Vertical glue mixer specification: | |

| 拌胶桶直径Barrel diameter | 08OO*8OOmm |

| 产量 Machine capacity | 150kg per cycle |

| 电机容量Motor power | 3kw |

| 重量 Machine weight | 100kg |

Main features and technical parameters:

1. Suitable process: dispensing, mixing, mixing, quantitative potting and potting. Large flow mixer AB rubber mixer automatic mixing equipment

2. Suitable material: AB adhesive (polyurethane, PU adhesive, silicone, epoxy resin)

3. Glue mixing, quantitative glue mixing, fully automatic operation, one machine to achieve two functions.

4. Glue control pump body: screw pump, gear pump, mixing mode: dynamic mixing.

5. The proportion and amount of glue can be adjusted. You only need to change two numbers on the touch screen. It can be used at any time, with high matching accuracy, and can be matched as required to save glue. Large flow mixer AB rubber mixer automatic mixing equipment

6. Bucket size: 20L for bucket A, 20L for bucket B, and 3L for bucket C (detergent bucket).

7. The operation is simple and convenient, the program editing is simple, the cleaning is free, and the disassembly and assembly is simple and convenient. The two types of glue A and B are directly put into two corresponding buckets, and the glue is only prepared when filling. The workers only need to press the start switch. 8. Glue proportion: any fixed proportion between 1:1 and 10:1.

9. According to the glue performance, A glue barrel is equipped with a mixing device to prevent sedimentation, and a heating device can also be added. B glue barrel is well sealed to prevent volatilization, and a liquid level sensing device can also be added. When the glue is lower than this level, it will automatically remind and add corresponding glue Large flow mixer AB rubber mixer automatic mixing equipment

10. Proportioning accuracy: ± 1%, dispensing accuracy: ± 2%.

11. It is convenient to clean. The mixing part of A and B glue only has the mixing tube at the glue outlet, so the cleaning part only has the mixing tube, and other parts need not be cleaned. If you want to fill the glue after work or stop for a period of time, you just need to take down the mixing tube, soak it in the cleaning agent or clean it immediately, without consumables. 12. Glue flow: 5g-40g/S (adjustable, depending on the glue).

In the business phone input box,Please enter National telecommunication code and phone number,format like this +86 13385391681

*Content