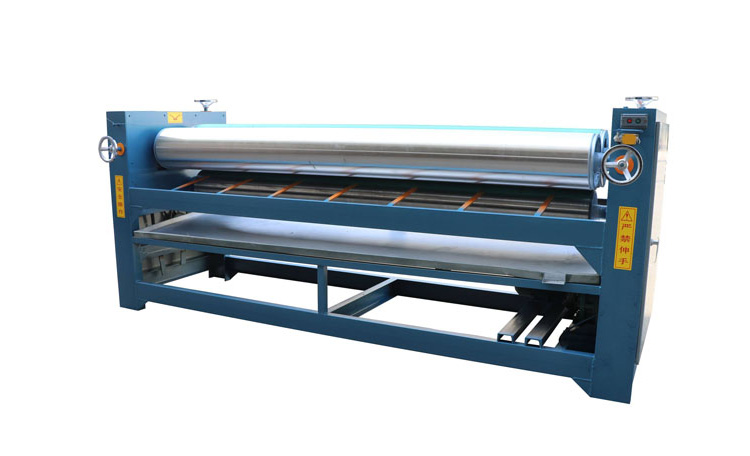

The 2700 × Φ 305 three roll glue coating machine is a mechanical equipment specifically designed to evenly apply liquid glue to various material surfaces, such as artificial boards. The following is an introduction to the technical structure of the glue coating machine:

1、 Overall structure

The 2700 × Φ 305 three roll glue coating machine is mainly composed of a frame, a glue coating roller, an extrusion roller, a transmission device, a glue supply system, and other parts.

2、 Rack

The frame is the supporting part of the glue coating machine, made of cast or welded steel sections, with sufficient strength and stability, used to support components such as glue coating rollers, extrusion rollers, and transmission devices.

3、 Coating roller and squeezing roller

Roller coating: Roller coating is divided into upper roller coating and lower roller coating, with a length of 2700mm and a diameter of Φ 305mm. Rubber rollers are usually made of cast iron or steel pipes, and the roller is covered with hard rubber with grooves on the surface to better apply glue.

Squeezing roller: The diameter of the squeezing roller is usually Φ 271mm (electroplated), and its linear speed is slightly lower than that of the coating roller, mainly used for scraping and adjusting the coating amount. The position of the squeezing roller can be set next to the upper or lower roller according to actual needs.

4、 Transmission device

The transmission device adopts a chain wheel transmission method, with a motor power of 4KW and a voltage of 380V. The transmission device is responsible for driving the rotation of the coating roller and extrusion roller, ensuring the smooth progress of the coating process. The rotation direction and speed of each roller can be freely adjusted with the speed of the production line to meet different production needs.

5、 Glue supply system

The glue supply system is responsible for providing glue to the glue roller. For the extrusion roller next to the upper coating roller, the glue pump supplies glue through the rubber hose and stores the glue in the groove formed between the coating roller and the extrusion roller; For the squeezing roller next to the bottom glue roller, the glue is directly supplied from the glue tank, and the amount of glue applied is not affected by the height of the glue tank liquid level.

6、 Glue application form and characteristics

This glue machine adopts a single-sided glue application form, which has the advantages of uniform glue application, simple operation, and adjustable glue amount. Meanwhile, due to the use of a three roll structure, the amount of glue applied can be effectively controlled, improving the quality of glue application.

| PARAMETERS | |

| Model | 2700×Φ305 with three rollers |

| Assembly form | Front and rear assembly |

| Gluing | single side |

| Transfer method | sprocket drive |

| Length of roller(mm) | 2700 |

| Diameter of roller(mm) | Φ305 |

| Diameter of Squeeze roll mm) | Φ271(plating) |

| Liner speed(m/min) | 30 |

| Motor(KW) | 4 |

Suitable for single-sided or double-sided adhesive coated artificial boards, such as plywood, multi-layer boards, veneer boards, furniture boards, etc.

The rubber roller is made of high-quality rubber material and is precision processed by lathes and grinders to ensure even coating.

The equipment line speed can reach 30m/min, improving production efficiency.

In the business phone input box,Please enter National telecommunication code and phone number,format like this +86 13385391681

*Content