Nowadays, the use of hot press is more and more in the factory buildings. Therefore, in the process of normal use of hot press, how to carry out correct operation and subsequent maintenance needs to be in-depth studied. For the operation, repair and maintenance of the hot press, it is necessary to find the deficiencies in the actual operation process on the basis of a sound working system, and make targeted improvements to achieve the durable, safe and efficient hot press in the daily work process, and make an important contribution to the improvement of the industrial level and work efficiency of the wood-based panel factory.

When the hot press is in normal use, whether it is operated or maintained, it needs to be actually managed according to the work procedures [1]. Because the hot press will have a very important impact on the work of wood-based panels, the operation, repair and maintenance of the hot press should be strictly managed according to the relevant technical standards. Moreover, with the rapid progress of science and technology, the hot press has changed greatly in terms of technology and operation methods. Therefore, in order to better realize the operation, repair and maintenance of the hot press, it needs to be continuously improved.

Hot press operation process

The operation process of the hot press mainly includes preparation for inspection, startup, normal operation and shutdown operation, which will be discussed in this paper.

Preparation and inspection

The hot press needs to be checked before the official start and actual operation. Because of the universality of the hot press, it is very easy to ignore the relevant detailed rules of the hot press operation in the daily actual operation process, which has a serious impact on the subsequent normal operation and use of the hot press, and also brings great potential safety hazards to the on-site work. Therefore, first of all, the relevant operators should confirm the pressure and temperature during the operation of the hot press according to the relevant process standards and process requirements, and ensure the continuity of the pressure and temperature [2]. Secondly, before the official start, all parts of the hot-press, the surface of the steel strip and the metal structure need to be cleaned, and there should be no other impurities. Finally, carefully check the pressure and temperature related to the operation and the condition of the transmission part during the normal use of the lower level.

Startup process

For the hot press, starting is a very simple operation. As long as it is carried out according to the corresponding rules and regulations and operating procedures, there will be no major problems. Because the actual operation is very simple, during the normal operation of the hot press, some of the actual operators did not pay enough attention to the startup operation, and there was a loose state during the actual operation. Therefore, the following aspects should be paid attention to during startup operation. First of all, it can ensure the normal start of the hot press, enable the working parts of the hot press to realize the normal start, and enable the slab to be continuously loaded into the press without interruption or bad problems. At this time, the processing operation procedure should be started in time. Thirdly, if there are automatic control procedures for the operation of the hot press, all these procedures should be opened during actual use. In the actual operation process, automatic and manual operation are combined to reduce the probability of accidents.

|

Nominal pressure(T) |

100T |

|

he directtion of boards into Into |

Transverse |

|

Number of layers(layer) |

11 |

|

Layer spacing(mm) |

130 |

|

Number of hot plates |

12 |

|

Format size(mm) |

1370*2700*52 |

|

Number of piston cylinder(个) |

6 |

|

Diameter(mm) |

ɸ280 |

|

Working Stroke(mm) |

1450 |

|

Withstand voltage (Mpa) |

≤25 |

|

No-loading closing time(S) |

15 |

|

Low-pressure pump flow(L/min) |

87 L/min |

|

Allowable pressure(Mpa) |

<=3 |

|

Power (Kw) |

22 |

|

High-pressure pump flow(L/min) |

25 |

|

Allowable pressure(Mpa) |

<=25 |

|

Power(Kw) |

11 |

|

Overall dimensions(mm) |

1370*3700*4600 |

|

Control methods |

Full automatic |

|

Electric appliance |

Schneider |

|

Gauge |

Wuxi |

|

Hydraulic valve |

Jinan |

|

Framework form |

Gantry Framework |

| The thickness of the upper and lower beams(mm) | 900*900 |

| the plate thickness of main part framework(mm) | 40*4 |

| Top plate thickness(mm) | 30 |

| Column Width(mm) | 400 |

| Total weight(T) | About 45 ton |

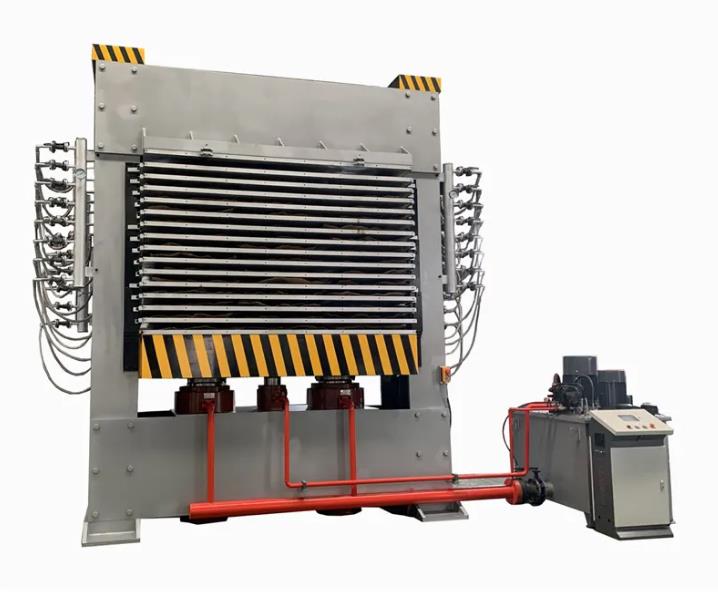

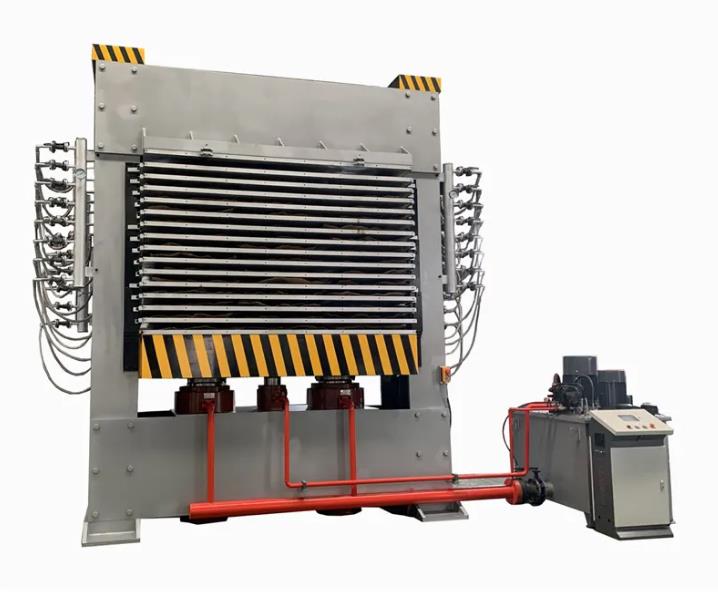

Production advantages:

1.Framework adopt high quality steel, heighten and thicken, solid and durable.

2.New model high grade pump station, lower noise, more stable performance.

3.Adopting new model four-bar linkage synchronizer, synchronous effect more stable.

4.Cylinders adopt high temperature resistance oil seal and macro molecule heat insulation board 5.All adopt high grade electrical appliance and hydraulic parts, very low failure rate.

In the business phone input box,Please enter National telecommunication code and phone number,format like this +86 13385391681

*Content