Veneer drying is a very significant stage in the full production process of plywood. If the moisture content inside veneer is too high or different, it will directly affects the final quality of plywood. Usually,the moisture content of veneer is required to be 8%-14%, which is most ideal for the quality of plywood veneer, so the veneer dryer is one crucial machine to complete the veneer drying.

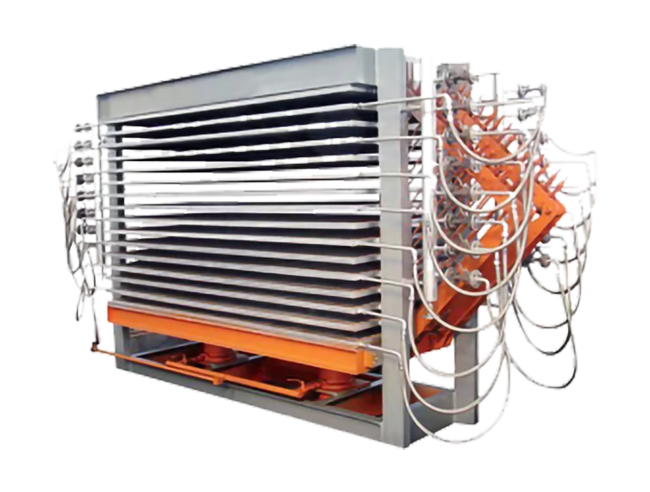

The hot platen core veneer dryer, which is also called square tube veneer dryer or breath type veneer dryer. The main application of this type veneer dryers is for core veneers,especially for the thick veneer above 1mm, for it can lead to the much flatter surface of core veneers. The heating source includes both thermal oil and steam.

| Model | GY81-4×8/400 |

| Quantity and diameter of Cylinder | 2 unitsΦ320mm |

| Diameter of cylinder | 360mm |

| Origin of cylinders | Wuxi |

| Certification | ISO 9001-2000,CE |

| Overall Dimension | 3700*3100*1370mm |

| Frame thickness | 35-40mm |

| Pressure capacity | 400T |

| Cylinder stroke | 800mm |

| Diameter of Lifting Cylinder | Semi-automatic control |

| Hydraulic system | 25MPa |

| compression resistance | |

| Main motor | 7.5KW |

| Pressurized motor | 5.5KW |

| Width between nether and top crossbeam | 1700mm |

| Main pump | 100:100 Double-vane pumps |

| Pressurized pump | 10ml/rev plunger pump |

| Dimension of hot plates | 2700*1370*40mm |

| Quantity of hot plates | 12-16PCS |

| Height of space between plates | 70mm |

| Motor power | 4kw |

| Working type | Manual or automatic |

| Time of open-close | Less than 15S |

| Maximum working space | 70-100mm |

| Maximum work pressure | 4Mpa |

| Height of up pallet | 900-1000mm |

| Height of middle pallet | 400mm |

| Height of down pallet | 900-1000mm |

| Heating medium | Thermal Oil/Steam |

| Warranty | 1 year |

Note:This is only one of our plywood dryer machine models. We have professional technology team to design new equipment according to different requirements and applications.

The selection of the veneer dryer needs to provide us with several data to ensure we provide the best solution for you: 1. What is the thickness of the veneer? 2. What is the throughput for 10 hours? 3. What is the moisture content of the veneer? 4. what’s the wood species of the veneer? 5. what’s the heating source, thermal oil or steam? Etc.

1.The machine equipped with symmetrically level spring synchronous closing mechanism, the pressing plates and core can connect and disconnect at the same time.

2.Rack uses framework of institutions, up inlet hydro-cylinder, easy installation and less infrastructure investment.

3. the moisture can remove and exhaust fast with the specially crafted hot plates

4. estimated daily capacity:20cmb/24 hours(4*8ft,1.5mm thickness veneer,moisture 10% - 70%)

5.Seamless pipe hot platen, low investment cost. 6. The machine adopts lever spring simultaneous closures system, which makes each core veneer closed simultaneously

7. After special processing, hot platen has a favorable tide exhaust tank on both sides, which makes veneer exhause wet gas fast and efficiently.

8. The self-developed PLC system can set the number and time of exhaust wet gas according to the humidity of core veneer.

9. Oil cylinder is easy to maintain, and also its failure rate is low. Besides, it adopts a upper cylinder mode.

10.Using International standard steel plate and electrical components

11.The plane heating plate of this machine is formed by welding many pieces of quadrate tube, thus temperature is uniformly distributed.

12.The hot plate is made of aeronautical materials , so its service life is longer and is of high flatness to ensure the quality of the finished board.

13. Detachable frame and solid cylinder with a stable function, full automatic hydraulic system!

14. Veneer dryer thickness 0.6-3.6mm plywood veneer dryer

15. Working width 2200mm plywood veneer dryer

In the business phone input box,Please enter National telecommunication code and phone number,format like this +86 13385391681

*Content