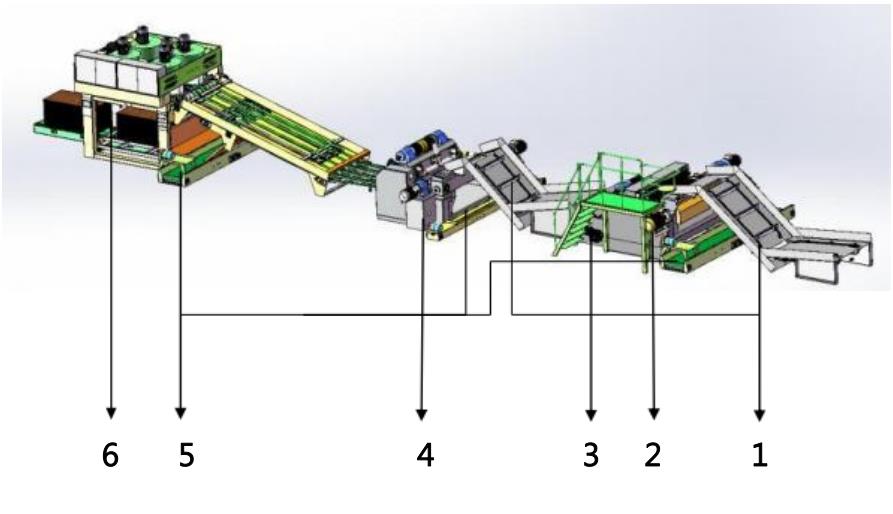

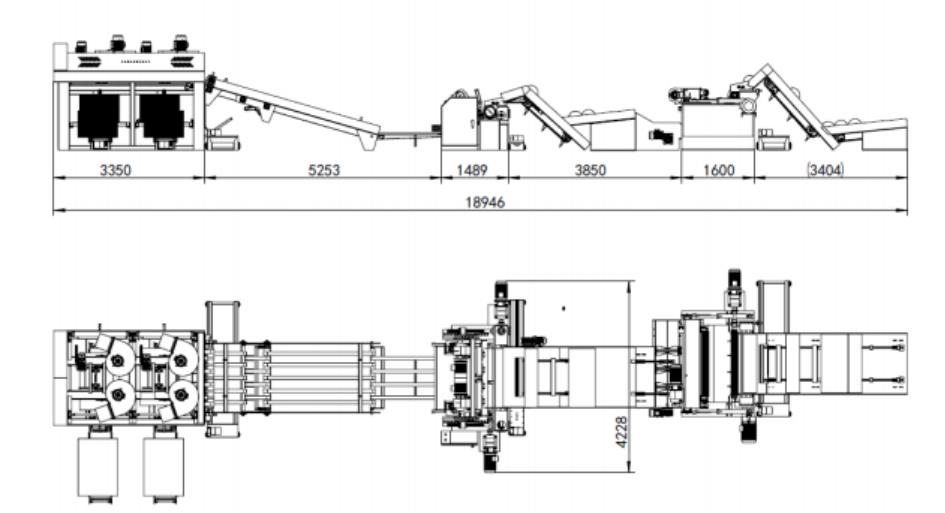

Installatioin size: 19*4.5 meter

Total power: 86 kw

Capacity: 40-80m3 (veneer thicknees:1.7mm & working time: 8 hours)

PART I Equipment and Parameter

|

Part name |

Quan. |

Specifications |

Photos |

|

1. Log loader |

2 sets |

Loading speed: 30m/min |

|

|

Motors:1.5kw*2 |

|||

|

Max. log diameter: 600mm |

|||

|

Worm gear reducer |

|||

|

2. debarker |

1 set |

Log length:970- 1400mm |

|

|

Log diameter:600mm |

|||

|

Veneer thickness:1.0-4.0mm |

|||

|

Output speed:60m/min |

|||

|

Mainmotor:7.5kw*2 |

|||

|

Feeding motor: 5.5kw |

|||

|

3. log adjuster |

1 set |

Max log dia.: 600mm |

|

|

Cross conveyor |

|||

|

Motor:1.5kw*2 |

|||

|

Worm gear reducer |

|||

|

4. peeler |

1set |

Log length:970- 1270- 1400mm |

|

|

Log diameter:400mm |

|||

|

Veneer thickness:0.3-6.0mm |

|||

|

Rotary speed:60- 120m/min |

|||

|

Linear guide rail(Taiwan) |

|||

| Single roller Motor:11kw Double roller motor:5.5kw*2 Feeding servo motor:11kw Cutting servo motor: 2.2kw |

|

5. Wast conveyor |

3 sets |

Length:4000mm |

|

|

|

Cross conveyor |

||||

|

Motor:0.75kw |

||||

|

6. Auto- |

1 set |

Veneer size: 1300*500mm/ 1300*670mm / 1300*880mm |

|

|

|

Veneer thicknees: 0.5- 10.0mm |

||||

|

Working speed: |

||||

|

Vaccum motor:4kw*4 |

||||

|

Double grading |

stacking and Automatic of veneer |

|||

|

Remark |

Installatioin size: 19*4.5 meter |

|||

|

No. |

Name of commodity |

Quantity |

Unit price |

Amount |

|

1 |

Log loader |

2 sets |

USD2,350 |

USD4,700 |

|

2 |

debarker |

1 set |

USD7,650 |

USD7,650 |

|

3 |

log adjuster |

1 set |

USD1,617 |

USD1,617 |

|

4 |

peeler |

1 set |

USD19,117 |

USD19,117 |

|

5 |

Wast conveyor |

3 sets |

USD880 |

USD2,640 |

|

6 |

Auto-double stacker |

1 set |

USD22,060 |

USD22,000 |

|

FOB FEE |

1*40hq+1*20gp |

USD1,176 |

||

|

Total |

Fully line |

USD58,900 |

||

A 4-foot veneer production line with a palletizer has demonstrated significant advantages in the modern wood processing industry. Its efficient automated production process greatly improves production capacity, doubling production efficiency compared to traditional manual operations and effectively shortening the product launch cycle.

The precise operation of the palletizer ensures neat and stable stacking of single boards, reduces losses and safety hazards during manual handling, and improves product quality and production line safety. In addition, the production line integrates an intelligent control system that can flexibly adjust production parameters, adapt to diverse product demands, and enhance the company's market competitiveness.

Automated monitoring and maintenance functions have reduced equipment failure rates, extended the service life of production lines, and also reduced labor costs.

The 4-foot veneer production line with a palletizer has become an important driving force for the transformation and upgrading of the wood processing industry due to its efficient, safe, and flexible production characteristics, helping enterprises achieve high-quality and sustainable development.

In the business phone input box,Please enter National telecommunication code and phone number,format like this +86 13385391681

*Content