Plywood hot press machine is a key equipment for producing plywood. Proper use can ensure production safety and product quality. The following precautions should be kept in mind:

1. Pre operation inspection: Before starting up, it is necessary to check whether all components of the hot press machine are intact, including the heating system, hydraulic system, electrical system, etc., to ensure that there is no oil leakage or electric leakage, and that all connection parts are securely fastened.

2. Accurate parameter settings: Based on the process requirements of plywood, accurately set parameters such as hot pressing temperature, pressure, and time to avoid quality defects in the board due to improper parameters.

3. Adequate safety protection: Wear protective equipment such as insulated gloves and goggles during operation. It is strictly prohibited to insert hands or other parts of the body between the pressure plates during the operation of the hot press machine.

4. Regular maintenance: Clean, lubricate, and tighten the hot press regularly, replace worn parts in a timely manner, and ensure long-term stable operation of the equipment.

5. Abnormal situation handling: If abnormal sounds, odors, or pressure/temperature fluctuations are found during operation, the machine should be stopped immediately for inspection and troubleshooting before resuming production.

Following these precautions can effectively improve the efficiency and safety of the plywood hot press machine.

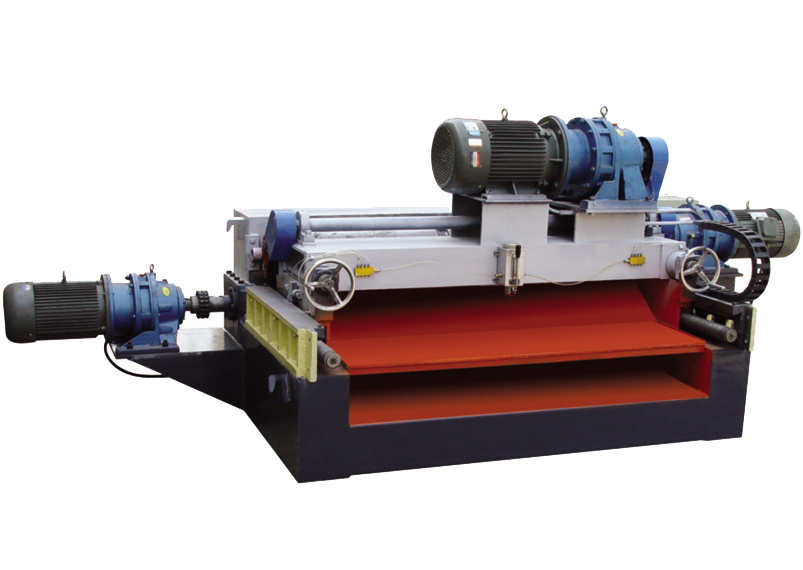

Use process of rotary cutting m

Use process of rotary cutting m

01 January,1970

What’s the Correct Moisture C

What’s the Correct Moisture C

01 January,1970

What Are the Advantages of Mesh

What Are the Advantages of Mesh

01 January,1970

The Problems and Solutions of c

The Problems and Solutions of c

01 January,1970

The rotary cutting machine asse

The rotary cutting machine asse

01 January,1970

How to maintain the wood veneer

How to maintain the wood veneer

01 January,1970