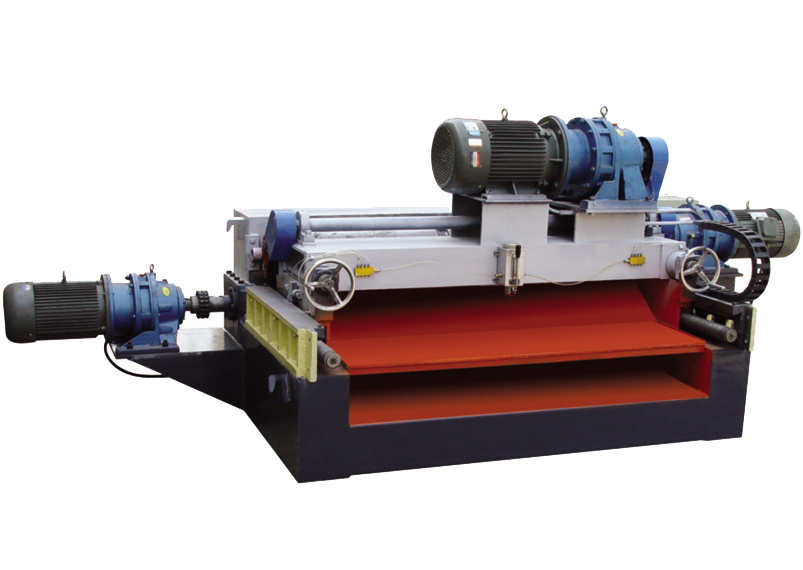

As a key equipment in modern plywood production, the cardless veneer rotary cutting machine has significant technical advantages compared to traditional carded rotary cutting machines, mainly reflected in the following aspects:

Breaking through the limitations of wooden cores

Adopting a cardless design, it completely eliminates the limitation of traditional carded shafts on the diameter of the wood core, achieving 100% wood utilization rate. The minimum diameter of veneer rotary cutting can reach 3cm, and the raw material saving rate is over 15%.

Intelligent constant line speed control

Equipped with a servo drive system and real-time diameter detection module, it automatically maintains a constant cutting line speed (adjustable from 0.5-2.5m/s), ensuring that the thickness tolerance of the single board is controlled within ± 0.02mm, which is 30% better than the national standard.

Efficient production performance

The dual drive roller structure, combined with a hydraulic back pressure device, achieves a maximum feed speed of 60m/min and a daily output of over 25m ³ per machine, increasing production capacity by 40% compared to traditional models.

Adaptive cutting technology

Built in wood hardness detection system, automatically optimizes cutting parameters (feed rate/rotary cutting angle) to cope with complex working conditions such as scars and uneven textures, with a scrap rate of less than 2%.

Energy saving and environmental protection features

Reduce power consumption by 25% (main motor power of 55kW), control noise below 75dB, and cooperate with the central dust removal interface to meet green production requirements.

This equipment is particularly suitable for processing precious tree species and small diameter wood, with a shortened investment return cycle of 12 months, and has become a standard equipment for high-end plywood production.

What are the specifications of

What are the specifications of

01 January,1970

How to repair and maintain the

How to repair and maintain the

01 January,1970

What Are the Advantages of Mesh

What Are the Advantages of Mesh

01 January,1970

Use process of rotary cutting m

Use process of rotary cutting m

01 January,1970

Precautions for maintenance of

Precautions for maintenance of

01 January,1970

Precautions for using the log p

Precautions for using the log p

01 January,1970