How to control the amount of glue used in the production process of plywood

How to control the amount of glue used in the production process of plywood

March 25,2025

Controlling glue usage in plywood production is crucial for cost efficiency, product quality, and environmental sustainability. Excessive glue increases costs and may cause warping, while insufficient glue weakens bonding strength.

Main technical parameters of veneer peeling machine

Main technical parameters of veneer peeling machine

March 23,2025

Learn about the essential technical parameters of veneer peeling machines, including peeling diameter, spindle speed, thickness range, motor power, and more for optimal plywood production.

Dryer Machine Operation Guide

Dryer Machine Operation Guide

March 21,2025

This guide outlines dryer machine operation: pre-start steps include draining water, setting temperature, starting fans & drive system, and belt speed adjustments. During operation, maintain steady speed, adjust belt speeds for belt dryers,

Energy-Saving Tips for Veneer Dryers

Energy-Saving Tips for Veneer Dryers

March 19,2025

Veneer dryers use a lot of energy, especially for heating and electricity. To lower costs and use less energy, some smart changes have been made to the dryers: 1.Better Heat Exchangers: Replacing old round heat tubes with oval or rectangu

The Problems and Solutions of core veneer dryer machine

The Problems and Solutions of core veneer dryer machine

March 17,2025

The veneer core dryer has problems such as uneven drying, high energy consumption, and frequent malfunctions. This can be solved by optimizing the hot air circulation system, strengthening equipment insulation, introducing intelligent temper

Maintenance and Care of Dryers Machine

Maintenance and Care of Dryers Machine

March 14,2025

The maintenance and upkeep of the dryer are crucial, and it is necessary to regularly check the heating elements, temperature sensors, and ventilation system to ensure normal operation and efficient energy saving. Clean the heat sink and filter screen

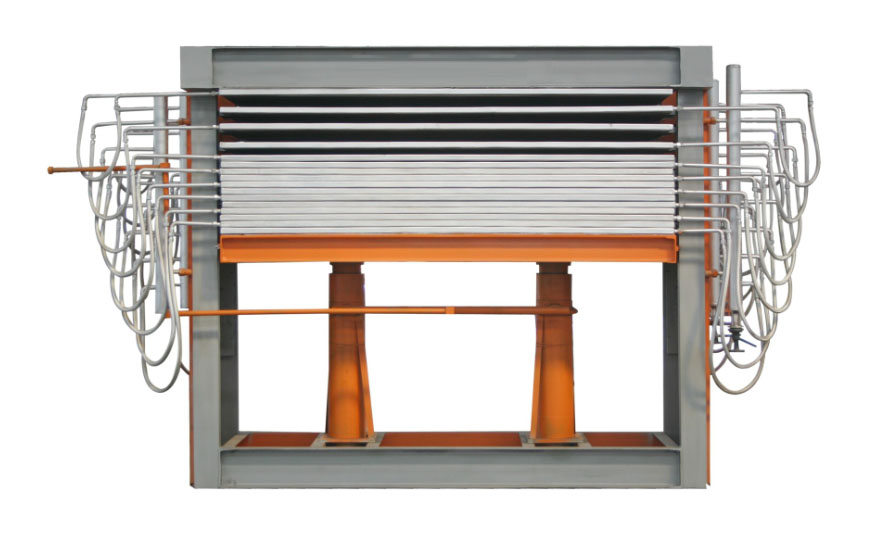

What Are Hot Press Veneer Drying Machine and Benefits

What Are Hot Press Veneer Drying Machine and Benefits

March 12,2025

The working principle of a hot press dryer is to heat and pressurize materials by stacking hot press plates, using steam to heat the plate surface while applying pressure to remove free water from the materials.

What Are the Advantages of Mesh-Belt Wood Veneer Dryer

What Are the Advantages of Mesh-Belt Wood Veneer Dryer

March 10,2025

The mesh belt veneer dryer has the advantages of fast drying speed, high efficiency and energy saving, easy operation, and good product quality. It is suitable for drying veneers of various sizes, and can evenly heat the veneers to reduce bo

What Are Directions of Veneer Feeding in Dryers

What Are Directions of Veneer Feeding in Dryers

March 08,2025

In dryers, Veneer boards can be fed in two main ways: longitudinal feeding and transverse feeding. The choice depends on how the boards are positioned relative to the direction of the wood fibers in the veneer.